Across industries, the need for reliable and precisely engineered steel structures is more important than ever. From telecom towers spreading 5G connectivity to high-voltage transmission lines powering cities, the foundation of these infrastructures lies in accurately processed steel angles and channels. Behind this accuracy stands a crucial partner: your CNC Angle Line Machine Manufacturer.

A high-quality CNC Angle Line Machine ensures every steel component is drilled, punched, cut, and marked with absolute accuracy. For companies in telecom, power transmission, and industrial fabrication, this level of precision makes all the difference.

Understanding the Growing Need for Advanced Steel Fabrication

Role of CNC Technology in Modern Infrastructure

As demand for stronger, safer, and more efficient infrastructure grows, fabrication companies can no longer rely on manual processes. Manual drilling, punching, and marking consume time and increase the risk of human error. CNC technology closes this gap by offering automation, repeatability, and high-speed performance.

Whether you’re building a microwave communication tower or a 400 kV transmission line, CNC steel processing ensures every angle meets design requirements.

What is a CNC Angle Line Machine?

A CNC Angle Line Machine is a computer-controlled system designed specifically for processing structural steel angles. It automates critical operations such as:

- Drilling

- Punching

- Shearing

- Cutting

- Marking

By integrating these functions into one machine, fabricators achieve unmatched precision and efficiency.

Key Functions of CNC Angle Processing

Drilling, Punching & Cutting Capabilities

These machines handle everything from creating bolt holes to cutting angles to length. With CNC controls, accuracy is maintained across hundreds of components.

Automated Marking Systems

Component marking ensures that during tower or structure assembly, each part is identified quickly, reducing on-site confusion.

Applications of CNC Angle Line Machines in Structural Steel Projects

-

Telecom Tower Fabrication

Telecom towers demand perfectly aligned holes and clean edge cuts to support high-speed assembly. CNC machines ensure:

- Correct hole placement

- Precise angle lengths

- Consistent component quality

This eliminates rework and speeds up tower installation.

-

Power Transmission Tower Manufacturing

Power towers carry massive loads, making precision essential. CNC machines ensure components are prepared exactly as per engineering drawings.

-

Industrial Steel Structures & Heavy Fabrication

Industrial buildings, warehouses, and steel plants all rely on accurately fabricated angles. CNC machinery ensures uniform part quality, essential for large projects.

Why CNC Angle Processing is Essential for Accuracy

Eliminating Manual Errors – CNC programming removes guesswork and ensures every piece meets specifications.

Speeding Up Production Timelines – What previously took hours with manual drilling is now completed in minutes.

Features of a High-Quality CNC Angle Line Machine Manufacturer

- Heavy-Duty Construction & Engineering

- User-Friendly CNC Controls

- Multi-Function Integration

- Long-Term Reliability & Support

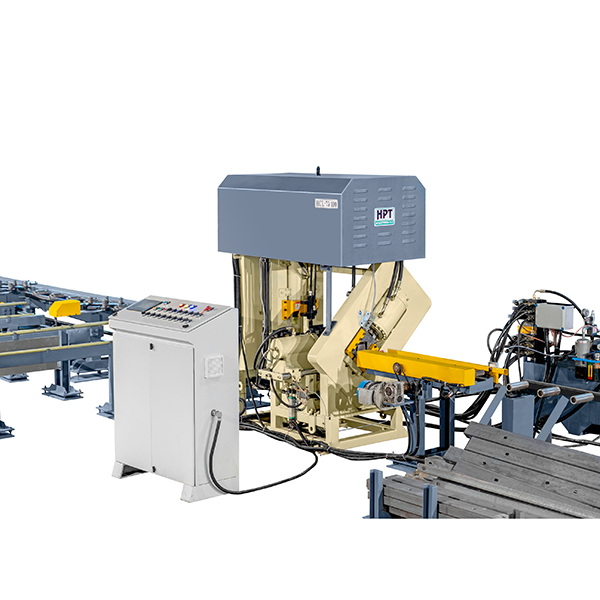

Why HPT – Hydro Power Tech Leads as a CNC Angle Line Machine Manufacturer

HPT stands out as one of the most trusted manufacturers in the structural steel industry:

Fully Featured CNC System – using advanced numerical controls for fast and accurate angle processing.

Superior Build Quality – these machines handle heavy structural steel with ease.

Customization for Industry Needs – every workshop has unique requirements, and HPT delivers tailored solutions.

Trusted by Telecom & Transmission Fabricators

Fabricators across India rely on HPT for consistent performance and reliability.

The Benefits of Integrating CNC Angle Lines in Your Workshop

- Improved Efficiency

- Material Savings

- Cost Reduction

- Higher Output Quality

Future Innovations in CNC Structural Steel Machinery

- AI-Based Production Optimization

- IoT-Driven Machine Monitoring

- Energy-Efficient Hydraulics

The Bottom Line

Choosing the right CNC Angle Line Machine Manufacturer is one of the most important decisions for any structural steel fabrication company. Precision, speed, and dependability define the future of steel manufacturing, and CNC machines deliver exactly that.

HPT – Hydro Power Tech stands at the forefront of CNC angle processing technology, empowering fabricators to produce high-quality steel structures efficiently and consistently. Whether you’re in telecom, power transmission, or heavy fabrication, investing in an HPT CNC solution is an investment in long-term reliability and growth.