Across the world, demand for telecom towers and power transmission structures is rising as connectivity and electricity infrastructure expand into every corner. Whether it’s a telecom mast delivering 5G signals or a high-voltage transmission line carrying power across states, these projects share one common foundation—precision-engineered steel structures.

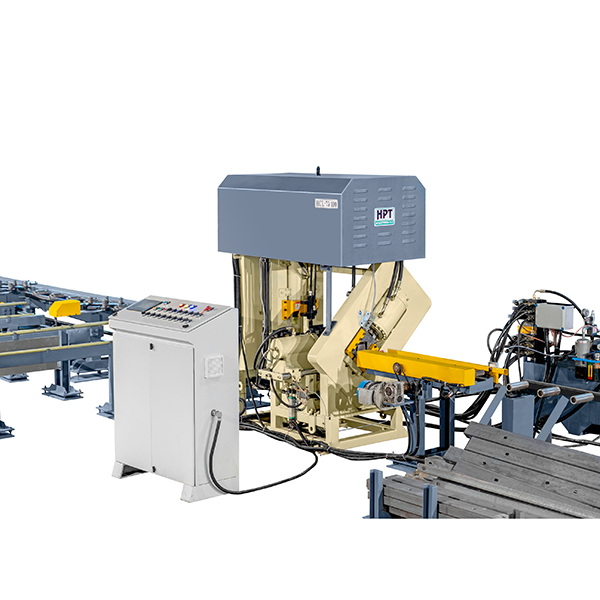

Behind these towers lies a quiet but powerful hero: the CNC Angle & Channel Line Machine. At HPT – Hydro Power Tech, we design advanced CNC Angle Line Machines and CNC Channel Line Machines that make tower fabrication faster, more accurate, and more reliable.

Why Telecom and Power Towers Need Precision

Building telecom and power transmission towers is no small task. Each tower requires hundreds of steel angles and channels, drilled, punched, and cut to exact specifications. Even a small error in alignment can weaken the structure, delay assembly, or lead to costly rework.

That’s why fabrication companies increasingly rely on CNC Steel Fabrication Machinery. These machines don’t just cut and punch—they bring consistency, speed, and repeatability that manual methods cannot match.

What is a CNC Angle & Channel Line Machine?

A CNC Angle Line Machine and a CNC Channel Line Machine are specialized systems designed to process structural steel sections like angles, channels, and flats. They perform operations such as:

- Drilling holes for bolts and fasteners.

- Punching slots or round holes for assembly.

- Cutting to precise lengths and angles.

- Marking identification codes or layout guides.

By combining these functions, a single CNC Drilling and Punching Machine replaces multiple manual processes. The result is faster production with fewer errors—a critical factor in large projects like telecom and power towers.

How These Machines Help in Telecom Tower Fabrication

Telecom towers require a large number of steel angles—often ranging from 40×40 mm to 200×200 mm—punched and drilled with absolute accuracy.

With an HPT CNC Angle Line Machine:

- Holes are drilled or punched in exact positions to ensure bolts align during assembly.

- Angles are cut to the correct lengths without secondary finishing.

- Markings guide workers during tower erection, reducing confusion on-site.

This level of precision shortens project timelines and improves safety since towers can be assembled without force-fitting parts.

Supporting Power Transmission Towers

Like telecom structures, power transmission towers depend heavily on steel channels and angles. The loads they carry are massive, and accuracy is non-negotiable.

A CNC Channel Line Machine for Steel Fabrication ensures that:

- Channels are drilled with exact bolt-hole positions.

- Cross-arms and braces fit seamlessly during tower assembly.

- Multiple parts can be processed in batches, improving productivity.

By automating these steps, manufacturers reduce errors, cut costs, and deliver stronger, more reliable towers.

Benefits of CNC Angle & Channel Line Machines in Tower Fabrication

- High Accuracy – Every hole, cut, and mark is controlled by CNC programming.

- Time Efficiency – Processes that once took hours are completed in minutes.

- Material Savings – Optimized cutting reduces scrap and waste.

- Lower Labor Costs – A single operator can manage what previously required several workers.

- Repeatability – Every part matches design specifications, ensuring smooth assembly.

- Better ROI – Faster production means more towers built in less time.

Why Choose HPT CNC Machines for This Job?

At HPT – Hydro Power Tech, we don’t just manufacture machines—we engineer solutions for industries that rely on precision. Our CNC Angle & Channel Line Machines stand out because:

- Heavy-Duty Build – Designed for structural steel fabrication in demanding environments.

- Versatility – Handles a wide range of angles and channel sizes.

- Advanced CNC Control – User-friendly programming for quick job setup.

- Integrated Functions – Drilling, punching, cutting, and marking in one machine.

- Proven Reliability – Trusted by fabricators serving telecom and power sectors.

- After-Sales Support – Training, servicing, and spare parts to keep operations running smoothly.

As a leading Angle Line Machine Manufacturer, HPT ensures every client gets machines that fit their production needs and long-term goals.

Future of Tower Fabrication with CNC Technology

As India and other countries invest in 5G networks, renewable energy, and expanded power grids, the demand for reliable towers will continue to grow. The next generation of CNC Steel Fabrication Machinery will bring:

- IoT-based monitoring for real-time machine health checks.

- AI-driven optimization for even better material utilization.

- Remote programming for flexible workshop management.

- Energy-efficient hydraulics to lower operating costs.

At HPT, we are committed to staying ahead of these trends, ensuring our clients have the technology needed to compete globally.

Final Thoughts

The strength of a telecom or power transmission tower starts long before it rises into the sky—it begins in the workshop, with the accuracy of its steel components. CNC Angle & Channel Line Machines play a vital role in making sure those components are cut, drilled, and punched with perfection.

At HPT – Hydro Power Tech, we are proud to be part of this process. Our CNC Drilling and Punching Machines, built for angles and channels, help fabricators deliver towers that stand tall and strong for decades.

Suppose your business is part of the telecom or power infrastructure supply chain. Investing in an HPT CNC solution is more than just a machine purchase. In that case, it’s a step toward reliability, growth, and leadership in the industry.