In sheet metal fabrication, accuracy isn’t just a nice-to-have—it’s the difference between a flawless project and a costly do-over. Among the many innovations shaping the industry, the hydraulic notching machine stands out for its ability to produce clean, precise cuts time after time.

Leading hydraulic notching machine manufacturers are constantly evolving their designs to meet the needs of modern fabrication shops. One company at the forefront of this evolution is HPT, known for engineering high-performance machines that combine precision, durability, and versatility.

Why Hydraulic Notching Machines Matter

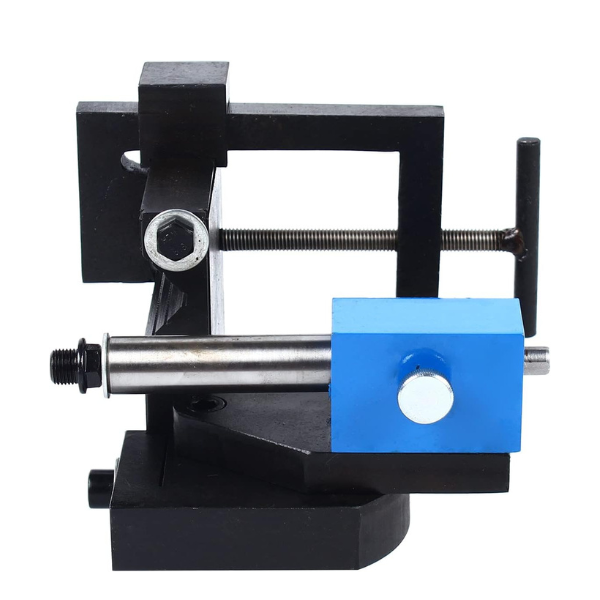

A hydraulic notching machine uses hydraulic pressure to deliver consistent, accurate cuts in sheet metal, angles, and profiles. Unlike manual methods, it minimizes distortion and ensures that each cut is identical to the last—crucial for industries where consistency drives quality and efficiency.

HPT’s hydraulic notching machines are designed to be more than just cutting tools—they’re precision metal cutting machines built to handle the demands of busy fabrication floors, construction sites, and manufacturing plants. With HPT, operators get the speed and accuracy they need without sacrificing durability.

Key Features of Modern Hydraulic Notching Machines

Top hydraulic notching machine manufacturers, like HPT, integrate advanced features that go beyond basic cutting:

- Precision Punching – Changeable dies allow for perfect hole placement in metal sheets, enabling quick setup for different projects.

- Angular Notching – Achieve clean, accurate angles—perfect for frame construction and sheet metal assemblies.

- Pipe Notching – Create flawless notches for pipe weld fittings, ensuring secure and accurate joints.

- Flat Metal Shearing – Make straight cuts without heat distortion or rough edges.

- Forming & Bending Options – With the right attachments, you can bend metal to exact specifications.

HPT machines combine these capabilities into a single hydraulic sheet metal machine, allowing fabricators to handle multiple processes without switching equipment.

The CNC Advantage

For customers seeking the highest level of precision, HPT offers CNC channel notching machines that take automation to the next level. By integrating computer numerical control, these machines execute complex cuts with perfect repeatability, making them a great choice for mass production and high-detail work.

Why HPT Stands Out Among Hydraulic Notching Machine Manufacturers

There’s a reason HPT is trusted in fabrication shops worldwide:

- Robust Engineering – HPT’s machines are built for long-term reliability with heavy-duty frames and precision-engineered hydraulics.

- Multi-Function Capability – From a simple sheet metal notching tool to an advanced precision metal cutting machine, HPT offers models to fit every production need.

- Custom Solutions – Whether you need a standalone unit or a full CNC setup, HPT works with you to tailor the machine to your workflow.

- Global Support – HPT ensures that operators get responsive after-sales service and easy access to parts, reducing downtime and maximizing productivity.

Applications in Sheet Metal Fabrication

HPT’s machines are used in a variety of industries:

- Construction – Cutting and notching beams, angles, and sheets for building frameworks.

- Automotive – Precision cutting of components for car bodies and chassis.

- Manufacturing – Fabricating equipment parts with consistent quality.

- Custom Metalwork – Crafting bespoke designs where accuracy is key.

The versatility of HPT’s hydraulic sheet metal machines means they can easily adapt to different materials and thicknesses without compromising performance.

Benefits of Choosing HPT Hydraulic Notching Machines

- Time Savings – Faster operations mean higher output in less time.

- Reduced Waste – Precise cuts mean less scrap metal and lower material costs.

- Operator-Friendly – Ergonomic controls and safety features make machines easier and safer to use.

- Consistent Quality – Every piece matches the last, ensuring project integrity.

When fabricators invest in HPT, they’re not just buying a machine—they’re gaining a partner in precision.

How to Select the Right Hydraulic Notching Machine

Before choosing from available hydraulic notching machine manufacturers, consider:

- Material & Thickness – Ensure the machine can handle the metals you work with most.

- Production Volume – High-volume shops benefit from CNC channel notching machines, while small shops may prefer manual-hydraulic hybrids.

- Available Functions – Look for models that can punch, shear, and bend as well as notch.

- After-Sales Service – Choose a manufacturer like HPT that offers long-term support and spare part availability.

HPT: Driving Innovation in Hydraulic Sheet Metal Machinery

HPT doesn’t just build machines—it builds trust. By focusing on high-performance hydraulic notching machines that deliver both speed and precision, the company has positioned itself as a leader in metal fabrication technology.

From sheet metal notching tools for small-scale jobs to precision metal cutting machines for industrial-scale production, HPT’s product line ensures there’s a solution for every fabrication challenge.

Final Thoughts

In the fast-paced world of sheet metal fabrication, you need more than just cutting power—you need accuracy, reliability, and versatility. The right machine can turn an ordinary job into a flawless finish.

By choosing an HPT hydraulic notching machine, fabricators gain access to cutting-edge technology, robust engineering, and the kind of support only a dedicated manufacturer can offer. Whether you’re in need of a CNC channel notching machine, a versatile hydraulic sheet metal machine, or a dependable precision metal cutting machine, HPT ensures you get the performance you need—cut after cut.