As the fabrication industry evolves, CNC punching machines are becoming an essential component in modern manufacturing. In 2026, these machines are not only taking over from manual systems but are also revolutionizing how industries approach tasks like punching, shearing, and notching. At HPT Ironworker, we manufacture high-quality hydraulic punching machines designed for a variety of fabrication needs. In this blog, we will dive into the key trends, applications, and benefits of hydraulic punching machines for heavy-duty tasks, and explain why investing in CNC punching technology is essential for businesses looking to stay competitive in the modern fabrication industry.

The Role of CNC Punching Machines in Modern Manufacturing

CNC punching machines offer the precision and efficiency that manual systems simply cannot provide. As industries demand higher quality and faster turnaround times, CNC technology allows manufacturers to meet these needs with ease. Whether you’re cutting intricate shapes or punching holes in sheet metal, a CNC punching machine ensures the job is done accurately and quickly, reducing human error and improving overall production efficiency.

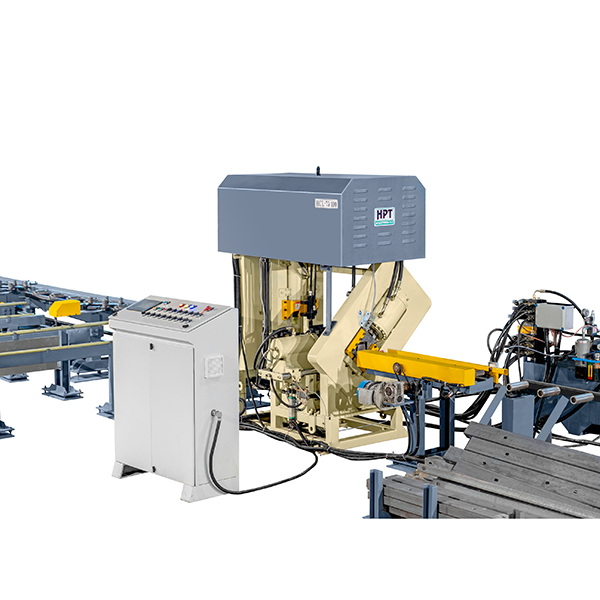

At HPT Ironworker, we specialize in creating machines that not only perform well but also integrate seamlessly into larger production lines. These hydraulic punching machines are a staple in industries like construction, automotive, aerospace, and energy, all of which require precision when handling heavy-duty tasks.

Why CNC Punching Machines Are Key for Precision and Efficiency

The demand for hydraulic punching machines has increased significantly due to their ability to perform heavy-duty tasks with consistent accuracy. These machines are perfect for industries that require reliable angle cutting and punching machines, capable of handling materials like steel, aluminum, and stainless steel.

One of the main advantages of using CNC technology in punching is its automation. CNC systems allow for more complex designs and faster setup times compared to manual systems, which makes them ideal for high-volume fabrication projects. Additionally, these systems can perform angle cutting and punching tasks without compromising on the quality of the end product. For businesses looking to scale production and maintain high standards, investing in a hydraulic punching machine is a smart decision.

Applications of CNC Punching Machines

CNC punching machines have a wide range of applications, especially when it comes to industries that require complex, repetitive tasks. Some of the most common uses of these machines include:

- Steel Fabrication: CNC punching machines are widely used in steel fabrication for creating holes and shapes in sheets or bars of steel.

- Construction: For the construction industry, CNC punching machines allow for precise holes in metal beams and framing materials, ensuring proper alignment during assembly.

- Automotive Manufacturing: Punching machines are essential for manufacturing parts and components for vehicles, from body panels to engine parts.

- Aerospace: Precision is paramount in the aerospace industry, where even a small error can have significant consequences. CNC punching ensures that every part is created to the exact specifications.

The tablet punching machine, for example, highlights a specific area of CNC punching technology, emphasizing its versatility across different sectors.

Understanding the CNC Punching Machine’s Hydraulic System

At the core of every hydraulic punching machine is its powerful hydraulic system. This system uses high-pressure hydraulic fluid to drive the punch and perform tasks like punching, cutting, and notching with incredible force. Compared to traditional mechanical systems, hydraulic punching machines offer several advantages:

- More Power: Hydraulic systems are capable of handling heavier materials and thicker gauges, making them ideal for heavy-duty tasks.

- Energy Efficiency: Hydraulic punching machines require less power than mechanical systems because they don’t rely on a flywheel or other mechanical parts, resulting in reduced energy consumption.

- Variable Speed: The speed of the punch can be controlled precisely, providing greater flexibility for different punching tasks.

With these advantages, it’s clear that hydraulic punching machines for heavy-duty tasks are invaluable in a variety of industries where high precision and speed are paramount.

The Impact of CNC Technology on the Fabrication Process

In recent years, CNC punching machines have transformed the way industries approach fabrication. Traditionally, punching machines were manually operated, which required skilled labor and left room for human error. However, CNC technology has automated the entire punching process, making it more efficient and reliable.

One of the key benefits of CNC punching is its ability to produce notching tool results with unmatched precision. Whether you’re working with a sheet of metal or a structural component, CNC punching machines provide the accuracy necessary for perfect fits. The integration of notching tools in CNC punching systems has made complex designs much easier to achieve, further pushing the boundaries of what’s possible in fabrication.

CNC Punching Machines for Complex Projects

For large-scale projects like power transmission towers and industrial frameworks, CNC punching machines can handle the increased workload and complexity. When it comes to machine angle precision, CNC punching ensures that each component is fabricated to the correct angle, which is crucial for the stability and safety of large structures. The consistent performance of CNC machines helps reduce downtime and rework, resulting in higher productivity and profitability for manufacturers.

For instance, in the construction of power transmission towers, CNC punching machines are used to process thousands of components, all requiring precise punching, cutting, and notching. The ability to streamline these processes through CNC automation ensures that these large-scale projects are completed on time and within budget.

The Advantages of Investing in CNC Punching Technology

Investing in a hydraulic punching machine offers numerous advantages that can help businesses stay competitive in a rapidly evolving market:

- Improved Precision: CNC punching machines eliminate the risk of human error, ensuring that each part is made to the exact specifications.

- Higher Efficiency: Automated systems speed up production, enabling manufacturers to handle more jobs in less time.

- Reduced Waste: CNC machines optimize material usage, reducing waste and lowering production costs.

- Versatility: CNC punching machines can handle a wide range of materials, from thin sheets to thick plates, making them suitable for various industries.

- Long-Term Durability: With proper maintenance, CNC punching machines have a long lifespan and require minimal downtime, providing a solid return on investment.

Conclusion

As the modern fabrication industry continues to grow, CNC punching machines are becoming an essential part of the manufacturing process. Whether you need to punch holes, cut angles, or notch steel, hydraulic punching machines provide the precision, speed, and reliability necessary for high-quality production.

At HPT Ironworker, we manufacture state-of-the-art hydraulic punching machines designed to meet the demands of industries across the globe. With our CNC technology, we ensure that your projects are completed with the utmost efficiency and precision. For businesses looking to enhance their fabrication capabilities, investing in CNC punching technology is not just an option—it’s a necessity for staying competitive in today’s fast-paced manufacturing environment.