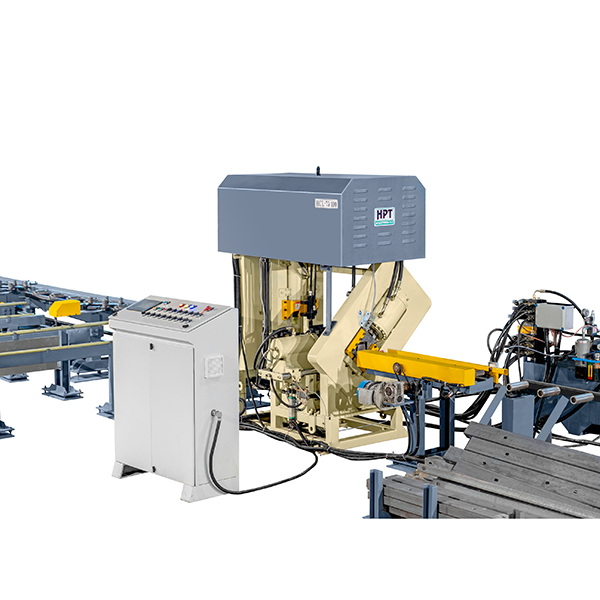

When it comes to building reliable and long-lasting steel structures, accuracy and consistency are non-negotiable. From power transmission towers to industrial frameworks, every cut, punch, and notch must be executed with precision. This is where CNC channel notching machines from HPT are making a significant impact. These advanced systems are designed to handle complex channel steel fabrication tasks with unmatched efficiency, ensuring that industries can keep up with rising demands while maintaining the highest quality standards.

The Role of CNC Technology in Steel Fabrication

Steel fabrication has always been a demanding process. Traditional methods of punching, cutting, and notching often left room for error, wasted material, and slowed project timelines. With the introduction of CNC (Computer Numerical Control) technology, the landscape of fabrication has changed dramatically.

A CNC channel notching machine integrates automation, precision software, and durable tooling to create seamless operations. Every notch, hole, or cut is executed exactly as programmed, eliminating the inconsistencies that manual processes could not avoid. For industries like power transmission, where even the smallest error can compromise safety and structural integrity, this level of reliability is invaluable.

Why Notching Matters in Channel Fabrication

Notching may seem like a minor step in the fabrication process, but it is critical for the assembly of complex steel structures. Channels are often interconnected or bolted into larger frameworks, which requires clean, accurate notches at precise locations. Poorly executed notches can cause misalignment, weaken the structure, or lead to costly rework.

With HPT’s CNC channel notching machines, the process becomes seamless. These machines ensure accuracy within fractions of a millimeter, allowing channels to fit perfectly into the broader steel assembly. This precision is not just about speed—it directly contributes to the longevity and safety of finished structures.

A Complete Channel Steel Fabrication Line

HPT does not stop at just notching machines. The company delivers a complete channel steel fabrication line, designed to meet the growing demands of industries such as energy, construction, and heavy engineering.

This advanced line may include:

- CNC channel punching and shearing machines for accurate hole placement and smooth cuts.

- CNC channel drilling lines for creating precise bolt-ready holes.

- Automatic channel angle lines that integrate punching, shearing, marking, and notching tools in one workflow.

- Channel processing machines for towers, specifically engineered to meet the unique needs of power transmission and telecom infrastructure.

By combining these capabilities, HPT offers its clients a one-stop solution that simplifies fabrication, reduces downtime, and increases output.

Meeting the Demands of Transmission Tower Projects

One of the largest applications of channel fabrication is in transmission towers. These towering structures require hundreds of accurately processed channels and angles. Each notch, cut, and punch must align perfectly during assembly to withstand extreme weather, heavy loads, and decades of service.

For such projects, HPT’s channel processing machines for towers are an ideal choice. Built with robust design and powered by advanced CNC automation, they handle the high volumes and strict tolerances demanded by transmission tower manufacturers. This capability allows companies to deliver projects on time while maintaining the highest safety standards.

Benefits of HPT’s CNC Channel Notching Machines

Companies investing in HPT’s fabrication solutions gain more than just equipment—they gain a competitive edge. Here are the standout benefits:

- Unmatched Precision: Every cut and notch is exact, reducing rework and material waste.

- Higher Productivity: Automated workflows speed up production, enabling faster project delivery.

- Cost Efficiency: Less material waste and reduced labor costs translate into significant savings.

- Versatility: Machines can handle a wide range of channel sizes, making them suitable for multiple applications.

- Durability: HPT designs its machines for long-term performance, minimizing maintenance and downtime.

These benefits are particularly valuable in industries where timelines are tight and reliability is crucial.

HPT’s Commitment to Innovation

What sets HPT apart is not just its machinery, but its commitment to continuous innovation. The company understands that every client has unique requirements. That’s why HPT’s team of engineers designs customized solutions—whether it’s a CNC channel punching and shearing machine for a specific plant setup or a channel steel fabrication line tailored for high-volume tower projects.

HPT also provides comprehensive training, after-sales service, and technical support. This ensures that clients not only receive world-class equipment but also the knowledge and confidence to maximize its potential.

Looking Ahead: The Future of Channel Fabrication

As global infrastructure expands, the demand for stronger, more reliable steel structures will only grow. Traditional methods can no longer keep pace with these requirements. Automatic channel angle lines and CNC channel drilling line represent the future of fabrication, delivering both speed and precision.

HPT is at the forefront of this transformation. By integrating the latest technology with decades of industry expertise, the company empowers clients to stay competitive while setting new benchmarks in steel fabrication.

Conclusion

Fabricating steel structures is not just about cutting and shaping metal—it’s about creating the backbone of modern infrastructure. From power transmission towers to large-scale industrial frameworks, the stakes are high, and the margin for error is small.

With CNC channel notching machines and complete fabrication lines, HPT ensures that every project meets the highest standards of accuracy, efficiency, and reliability. For companies seeking to elevate their fabrication capabilities, partnering with HPT is more than an investment in machinery it’s an investment in the future of steel construction.