CNC Angle Line Machine: The Complete Solution for Structural Steel Processing

Advanced CNC Angle Line Machine for Precision Steel Processing

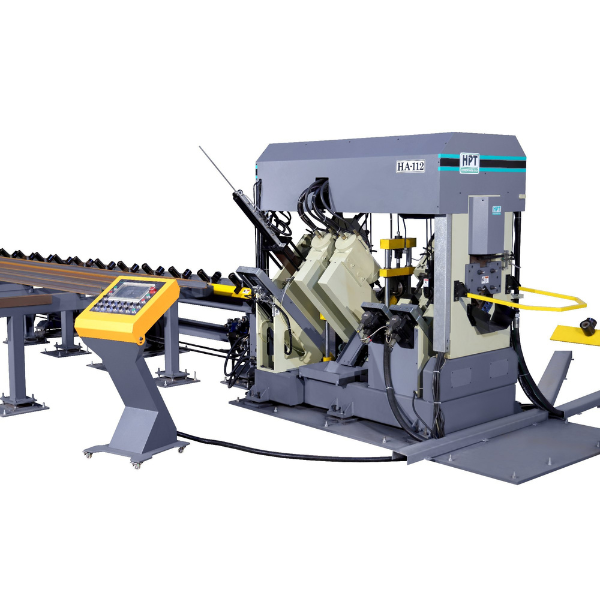

A CNC angle line machine is an advanced, high-precision system engineered for processing steel angles with unmatched speed and accuracy. It is designed to drill, punch, shear, and mark steel angles—essential for fabricating transmission towers, substation structures, and steel frameworks. From utility pole manufacturing to heavy steel construction, a CNC angle line machine offers the automation and performance needed in modern fabrication environments.

Choosing a trusted CNC angle line machine manufacturer ensures consistent production, long-term durability, and reduced manual intervention. A reliable CNC angle line machine optimizes workflow, reduces labor costs, and enhances output—making it a critical investment for any large-scale steel structure facility.

CNC Angle Line Machines: Power Meets Precision

These machines are built to handle the demanding needs of steel structure fabrication. Whether you’re processing 40×40 angles or large 200×200 sections, the CNC angle line machine simplifies what was once a multi-step, labor-heavy process.

From punching tower holes to drilling base plates and shearing structural components, each CNC angle line machine replaces multiple manual tasks with one streamlined, automated solution. The integration of CNC angle drilling line machine, punching, and shearing functions means faster production cycles and less room for human error.

When manufacturing transmission tower angle line machine components, precision and repeatability are non-negotiable. That’s why CNC angle shearing machines and angle punching systems are trusted by leading fabrication facilities worldwide.

With its unmatched efficiency, safety, and accuracy, a CNC angle line machine quickly becomes the backbone of any structural steel processing line—whether in tower fabrication, power infrastructure, or large-scale steel engineering.

TECHNICAL SPECIFICATIONS :

If you have any specific questions or need more information related to manufacturing CNC Angle and Channel Line Machines, feel free to ask!