In steel fabrication, precision isn’t a luxury—it’s essential. One wrong hole or misaligned shear, and the entire structure can go out of spec. That’s where CNC angle line machines come into play. Designed to process angles and channels with exact cuts, punched holes, and clear markings, they’re the secret behind flawless assembly in structural steel, tower construction, and even agricultural steel works.

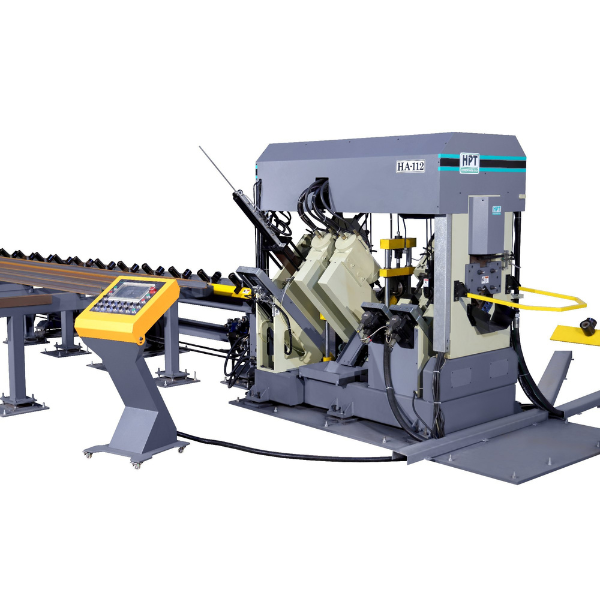

As a veteran in designing machinery that bridges durability and precision, HPT stands as a leader among CNC Angle Line Machine Manufacturers. Whether the job is tower components, structural storage frames, or electric power fittings, our machines are engineered to enhance accuracy and production speed—all under one roof.

Why CNC Angle Line Machines Are Game-Changers

Traditional angle processing involves endless indexing, manual marking, and separate punching stations. A CNC Angle Line Machine changes that. It transforms raw angle steel into finished components in one continuous cycle, from punching and marking to cutting—all controlled via CNC.

HPT’s HA and HC series machines shine because they consolidate these steps. A single machine handles multiple tasks while remaining adaptable—perfect for fabrication shops looking to streamline workflow, reduce floor space, and lower labor costs. Precision is raised, repeatability is guaranteed, and bottlenecks vanish.

From Raw Profile to Finished Part: How HPT Does It

Here’s a breakdown of what makes HPT’s CNC Angle Line Machines stand out, according to their detailed specs and design:

- Adaptive positioning and hold-down systems reduce cycle and clamping time—supporting higher throughput.

- Independent servo motor with separate hydraulic cylinders at each punch station enable concurrent operations, cutting idle time.

- Quick change tooling for punches and dies makes switching tasks fast and seamless.

- Rigid marking units, front-mounted shearing tools, and shear dies built for longevity ensure consistent quality.

- A hydraulic system engineered at zero pressure eliminates risks of overheating or leakage while saving power—no bulky accumulator system required.

- By eliminating the need for pneumatic systems, they cut costs and remove an entire maintenance component.

- High-speed hydraulic operations maximize cycle speed without sacrificing accuracy.

- Built with standard parts, they’re easy to source and keep running—important for minimizing downtime.

hydropowertech.in

All of this builds into one outcome: fabricators get a reliable machine that produces cleanly sheared, punched, and marked components—right out of the gate.

Applications and Industries

HPT’s CNC Angle Line Machine series is a perfect fit for:

- Tower line industries – Prepping structural angles with bolt-hole patterns and markings for quick assembly.

- Electric power fittings – Punching and marking load-bearing profiles for poles and supports.

- Steel structure and storage fabrication – Turning raw steel into finished frames and racking components.

- Agricultural and general fabrication – Where consistent components = efficient assembly lines.

Hydro Power Techhydropowertech.in

For small or mid-sized shops, this means a flexible, affordable production line. Larger players scale the setup with multiple machines for high-volume throughput.

What CNC Angle Line Machine Manufacturers Should Deliver

Choosing a supplier is just as important as the machine specs themselves. When evaluating CNC angle line machine manufacturers, look for:

- Robust engineering – A rigid frame with precision components that cut minute error margins.

- CNC adaptability – The ability to program different cuts, hole layouts, and material sizes quickly.

- Service and parts accessibility – Machines built with global parts and backed by fast support.

- Energy-efficient hydraulic systems – Lower running costs, less heat, and more uptime.

- Effortless tooling changes – To keep production flexible and operator errors minimal.

HPT checks every box, delivering machines that combine intelligent features with practical shop-floor execution. Their designs reflect real fabrication needs—not theoretical specs.

Buying Guide: Specs That Matter

Here’s a snapshot of key technical specs found in HPT’s lineup (models HA101 to HA253) to guide a purchasing decision:

| CNC ANGLE LINE MACHINES | ||||||

| Model | HA101 | HA102 | HA122 | HA163 | HA203 | HA253 |

| Functions | CNC Angle Punchin, Cutting & Marking Machines | |||||

| Angle Size min.(mm) | 35 X 35 X 3 | 35 X 35 X 3 | 35 X 35 X 3 | 35 X 35 X 3 | 35 X 35 X 3 | 35 X 35 X 3 |

| Angle Size Max. (mm) | 100 X 100 X 10 | 100 X 100 X 10 | 120 X 120 X 13 | 160 X 160 X 19 | 200 X 200 X 25 | 250 X 250 X 25 |

| Max. Punching Diameter (mm) | Ø32 | Ø 32 | Ø 32 | Ø 32 | Ø 32 | Ø 32 |

| Punching force (kN) | 500 | 500 | 650 | 800 | 1000 | 1000 |

| Tools Per Flange (No.) | 1 | 2 | 2 | 3 | 3 | 3 |

| Marking force (kN) | 900 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Shearing force (kN) | 1000 | 1000 | 1800 | 2200 | 4500 | 4800 |

| Models Available In Automatic & Semi – Automatic | ||||||

Choose a model based on the maximum material size, the number of punch heads needed, and whether you want semi-auto or full automation.

Maintenance & Productivity Tips

To keep your HPT CNC Angle Line running smoothly:

- Keep tooling lubricated and inspect punch/die contacts for wear.

- Replace hydraulic fluid on schedule and monitor filter cleanliness.

- Ensure operator panels and CNC controls stay updated, backed-up, and dust-free.

- Standard tooling systems simplify replacements and reduce setup time.

- Document job parameters in the CNC program library for fast recall.

These habits preserve the machine’s precision and sustain output quality—making your investment pay off reliably long-term.

Conclusion

If consistent accuracy, high productivity, and minimized error are your fabrication goals, a high-quality CNC Angle Line Machine is your solution. HPT’s machines offer precision, speed, and adaptability across multiple operations—all backed by thoughtful design and global support systems.

When comparing CNC Angle Line Machine Manufacturers, prioritize innovation that streamlines real-world work. Because in steel fabrication, your machine isn’t just cutting angles—it’s cutting costs, downtime, and error rates.