CNC Beam Line Machine: The Backbone of Structural Steel Processing

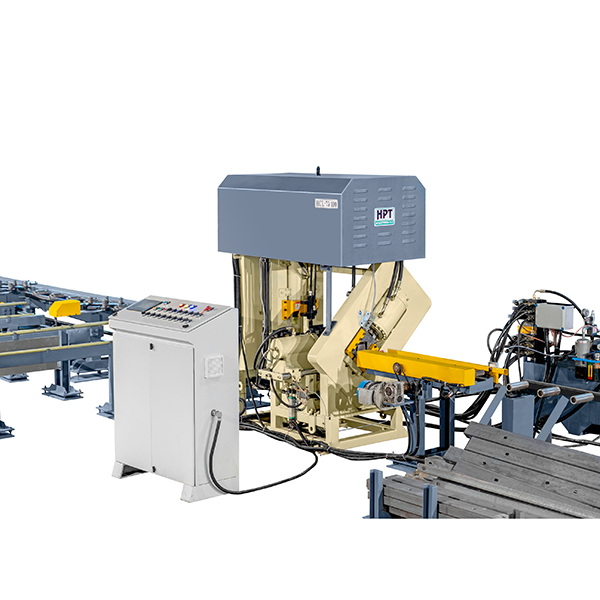

CNC Beam Line Machine for Structural Steel Processing

The CNC beam line machine is a high-performance solution engineered to automate the drilling, cutting, and marking of steel beams with unmatched accuracy. It plays a vital role in the production of steel structures, especially for large-scale construction projects, industrial frameworks, and transmission tower fabrication machine operations.

With the ability to handle H-beams, I-beams, and box sections, a well-built CNC beam line machine minimizes manual labor and maximizes productivity. Its automated system ensures smooth workflows, reduces material waste, and guarantees precise component fabrication in every cycle.

CNC Beam Line Machines: Built for Big Jobs, Trusted for Precision

When you’re fabricating steel beams for industrial sheds, warehouses, bridges, or transmission tower fabrication machines, precision isn’t optional—it’s essential. A CNC beam line machine replaces outdated, manual methods with an intelligent, computer-controlled workflow.

From beam marking to drilling to cutting, every step is streamlined. Whether you’re running a CNC H beam drilling line machine for vertical construction or a CNC I-beam processing machine for horizontal load-bearing structures, the result is the same: high-speed, low-error, cost-efficient production.

For any steel fabricator serious about scaling up, the CNC beam line machine quickly becomes the centerpiece of structural manufacturing—saving time, labor, and money while delivering consistent, project-ready results.

If you have any specific questions or need more information related to manufacturing CNC Angle and Channel Line Machines, feel free to ask!