Walk into any modern steel workshop today, and you’ll hear the rhythmic sound of beams being cut, drilled, and shaped with incredible precision. What was once a slow, manual, and error-prone process has been transformed by technology. At the heart of this transformation is one powerful piece of equipment—the CNC Beam Line Machine.

At HPT – Hydro Power Tech, we’ve seen firsthand how these machines have changed the way our clients work. From cutting down project timelines to improving accuracy to levels that were once unthinkable, CNC Beam Line Machines have become the backbone of steel fabrication across industries.

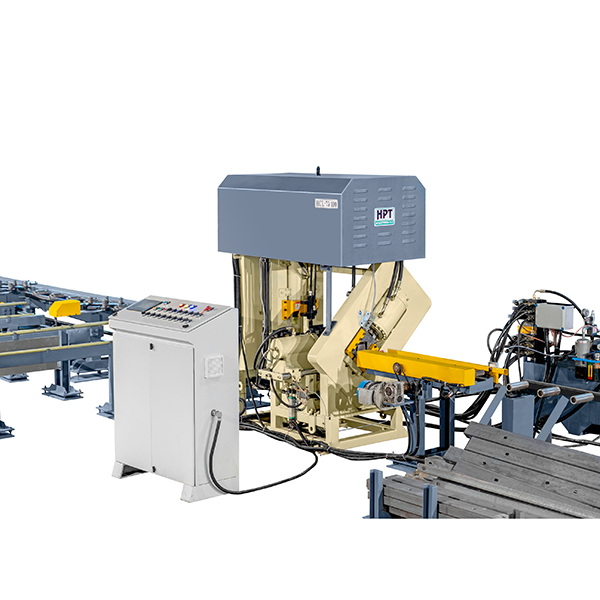

What Exactly is a CNC Beam Line Machine?

Think of it as your workshop’s multitasking genius. A CNC Beam Line Machine takes bulky steel beams—whether they’re I-beams, H-beams, or channels—and processes them with computer-controlled precision.

Instead of measuring, marking, and cutting beams by hand (a process that leaves plenty of room for mistakes), the CNC system follows digital instructions. Every cut, every hole, every notch is exactly where it should be. The result? Faster production, less wastage, and a big boost in confidence for fabricators and contractors alike.

The Workhorse Functions

What makes a CNC Beam Line Machine so valuable is the number of processes it handles under one roof. Here’s what it typically does:

- Drilling & Punching – Whether it’s bolt holes for a skyscraper frame or slots for an industrial plant, drilling is done cleanly and consistently.

- Sawing & Cutting – Beams are cut to size with millimeter precision, avoiding the common errors of manual cutting.

- Milling & Notching – Joints and fitting sections can be shaped directly on the machine.

- Marking – Need assembly marks or part numbers? The machine engraves them right on the steel, saving time during installation.

- Threading (on advanced models) – Adds screw threads so parts are ready for fastening without extra steps.

This combination is why fabricators often say, “One CNC Beam Line Machine does the work of three or four traditional machines.”

Why Fabricators Trust CNC Beam Line Machines

If you’ve ever worked with steel manually, you know how exhausting and risky it can be. CNC Beam Line Machines solve those challenges.

- Accuracy that builds trust – No more reworking parts because a hole is slightly off.

- Time savings – Projects that once took weeks can now be done in days.

- Less scrap, more savings – Optimized cutting means less steel ends up in the scrap bin.

- Safer working conditions – Automation keeps operators away from the most dangerous parts of the job.

- Better ROI – More projects completed in less time equals more revenue.

Where Are They Used?

These machines are not just for large factories—they serve a wide range of industries:

- Construction: From stadiums to metro stations, CNC Beam Line Machines ensure the steel skeletons of our cities are put together correctly.

- Infrastructure: Bridges, highways, and airports depend on precisely cut beams.

- Shipbuilding: Marine projects need beams that can handle pressure and weight, and CNC accuracy makes that possible.

- Industrial Plants: Power plants, oil refineries, warehouses, and manufacturing units rely on strong, properly fabricated structures.

- Energy Sector: Wind turbine towers and solar mounting systems are perfect examples of where beam-line precision matters.

Manual Processing vs CNC Beam Line Machines

Before CNC, fabricators had no choice but to rely on skilled workers marking and cutting beams by hand. The problem? Human error. Even the most experienced operator could be off by a few millimeters. On a small project, that might not matter much—but on a bridge or skyscraper, those errors multiply into serious problems.

With CNC Beam Line Machines, the process is automated. The machine doesn’t get tired, distracted, or make rough guesses. Every beam comes out right the first time. That reliability is why companies investing in CNC rarely look back.

How to Pick the Right CNC Beam Line Machine

Buying a CNC Beam Line Machine is like hiring a long-term partner for your workshop—you want to get it right. Here are some things to consider:

- Your workload – High-volume projects call for fully automated machines; smaller workshops might get by with semi-automatic models.

- Type of beams you process – Check the machine’s tonnage and ensure it matches your material needs.

- Software compatibility – A good machine integrates with CAD/CAM systems to save hours in setup.

- After-sales service – This is crucial. A strong machine is nothing without reliable support, spare parts, and training.

- Budget vs growth – While CNC machines are an investment, the savings in labor and time quickly make up for it.

At HPT – Hydro Power Tech, we don’t just deliver a machine—we work with you to understand your requirements and recommend the model that gives you the best long-term results.

Why Choose HPT Beam Line Machines?

Here’s what our clients often say about our machines:

- They’re built to last – designed with durability for heavy-duty projects.

- They’re precise – accuracy is at the heart of every HPT CNC system.

- They’re customized – no two workshops are the same, so we adapt machines to suit different needs.

- They’re globally trusted – manufactured to international quality standards.

- They’re supported – our after-sales team ensures you’re never left on your own.

This combination makes HPT machines more than just tools—they’re partners in progress.

Looking Ahead: The Future of CNC Beam Line Machines

Steel fabrication is only getting more advanced. Tomorrow’s CNC Beam Line Machines won’t just cut and drill—they’ll be smart, connected, and predictive. Imagine machines that can:

- Send alerts before a part wears out.

- Adjust automatically to reduce energy use.

- Connect with the cloud so you can track jobs remotely.

- Use AI to check quality and make real-time corrections.

At HPT, we’re already preparing for these changes because we know our clients want not just machines but future-proof solutions.

Final Thoughts

The CNC Beam Line Machine is more than just fabrication equipment—it’s a gateway to faster, safer, and smarter steel processing. In industries where accuracy and deadlines matter, these machines are not optional; they’re essential.

At HPT – Hydro Power Tech, we’re proud to build CNC Beam Line Machines that are powering infrastructure and industries across India and beyond. If you’re ready to upgrade your workshop and take your fabrication to the next level, our team is here to guide you every step of the way.