If you’ve ever worked in steel fabrication, you already know one thing—every millimetre matters. A wrong cut doesn’t just cost time; it wastes expensive steel, increases rework, and pushes deadlines further away. That’s why many fabricators are now switching to automation tools like the CNC angle line machine and the CNC channel line machine.

These machines may sound complex, but their purpose is simple: to cut, drill, and punch steel with unmatched accuracy—while keeping waste to a minimum.

Let’s break down how a CNC angle and channel line machine can make your fabrication process smarter, cleaner, and more profitable.

What Exactly Are CNC Angle & Channel Line Machines?

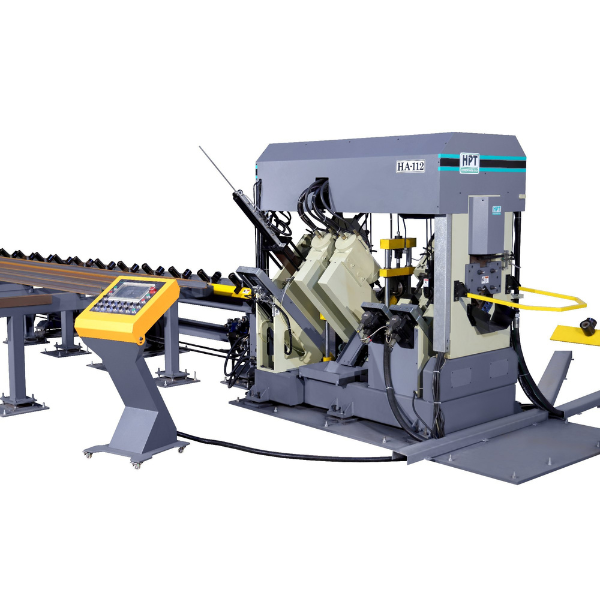

A CNC angle line machine is built to handle angles, while a CNC channel line machine is designed for channels. Both are fully automated systems that take drawings from your computer and bring them to life in steel.

Imagine uploading your CAD design, pressing a button, and watching the machine cut, punch, and drill with pinpoint accuracy. That’s the power of CNC technology—it removes the guesswork and gives you repeatable results, every single time.

For fabricators who deal with transmission towers, bridges, industrial buildings, or large infrastructure, a CNC angle line cutting machine is no longer a luxury. It’s a necessity.

Cutting Waste Down to Size

Steel isn’t cheap, and no business likes throwing money into the scrap bin. Here’s how CNC technology saves material:

- Smarter design integration – Since the machine reads CAD files directly, there’s no risk of miscalculated measurements.

- Nesting software – Think of it like Tetris for steel. The software arranges cuts in the most efficient way possible, leaving minimal leftovers.

- Error-free execution – A computer doesn’t get tired or distracted. Every cut is exactly where it should be.

- Consistency across batches – If you need 500 identical angles, you’ll get 500 identical angles—without extra waste in between.

The end result? Less scrap, lower material costs, and a greener, more sustainable workflow.

Accuracy You Can Rely On

In steel fabrication, precision isn’t just about looking good—it’s about safety and structural integrity. A hole drilled even a few millimetres off can cause major issues during assembly.

This is where CNC machines shine:

- Perfect positioning – Servo-controlled systems align material before every cut.

- Uniform punching & drilling – No uneven spacing or mismatched holes.

- Clean edges – Cuts are smooth and burr-free, saving hours of grinding.

- Built-in checks – Many machines monitor tool wear and pressure to maintain accuracy throughout the job.

When you use a CNC angle line cutting machine, you don’t just get precision—you get peace of mind.

Beyond Waste & Accuracy: The Extra Perks

While reduced waste and high accuracy are the main talking points, CNC machines bring more to the table:

- Speed & productivity – Automating multiple processes means faster turnaround.

- Lower labor dependency – One trained operator can manage the whole machine.

- Scalability – Whether you’re handling small custom orders or mass production, the machine adapts.

- Safety – Less manual cutting means fewer chances of workplace accidents.

It’s a win-win—better results, less stress on your team.

Choosing the Right CNC Angle Line Machine Manufacturer

Not all machines are built the same. If you’re investing in CNC equipment, choosing the right CNC angle line machine manufacturer is critical. Here’s what to look for:

- Build quality – Solid construction ensures long life and fewer breakdowns.

- Software support – Easy-to-use, upgradable software that works with your designs.

- Customisation – Machines tailored to your specific workflow.

- After-sales service – Reliable training, support, and spare parts when you need them.

A machine is only as good as the people behind it. Partner with a manufacturer who understands your industry and provides long-term support.

Real-World Impact

Think about a company building transmission towers. With manual methods, even a 2% error rate could result in hundreds of wasted steel pieces. Switch to a CNC angle and channel line machine, and suddenly, every piece fits perfectly. That’s thousands of dollars saved—not to mention faster project delivery.

The same goes for bridges, industrial structures, and even shipbuilding. In each case, accuracy and waste reduction directly translate into stronger profits and safer structures.

Final Thoughts

Steel fabrication is competitive, and staying ahead means working smarter, not harder. A CNC angle line machine or CNC channel line machine gives you the edge—less waste, better accuracy, faster production, and safer operations.

If you’re still relying on manual methods or older machines, now is the time to consider upgrading. A trusted CNC angle line machine manufacturer can help you choose the right equipment and set you up for long-term success.

At the end of the day, investing in a CNC angle line cutting machine isn’t just about technology. It’s about protecting your bottom line, delivering better results to your clients, and building a more sustainable future for your business.