Modern construction demands speed, accuracy, and efficiency. From skyscrapers to bridges and transmission towers, structural steel is at the heart of almost every major project. But raw beams don’t simply arrive ready for use; they require precise drilling, punching, cutting, and marking before assembly. This is where the CNC beam fabrication line comes in—a machine that has become the true backbone of modern construction.

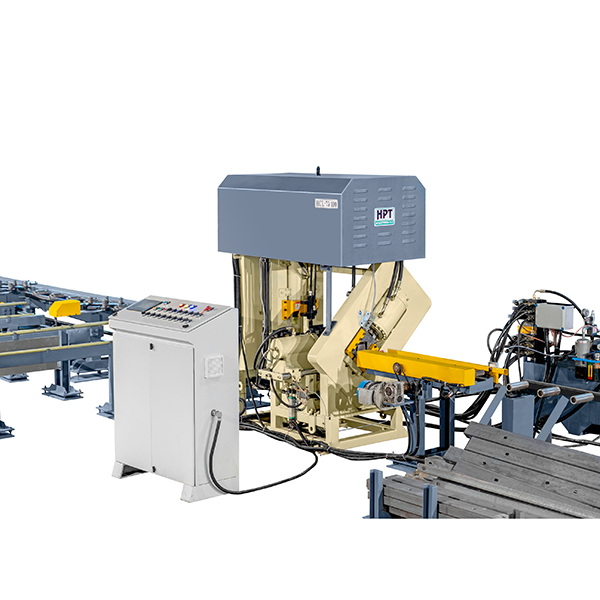

At the forefront of this technology are advanced systems such as the CNC H beam drilling line, CNC I-beam processing machine, and the structural steel beam line machine. Together, these solutions automate once labor-intensive processes, ensuring maximum productivity with minimal error.

The Shift Toward CNC Beam Fabrication

Traditionally, steel fabrication required multiple manual steps—cutting beams with saws, drilling holes with separate machines, and manually marking reference points. Not only was this time-consuming, but it also increased the risk of human error.

The beam fabrication line revolutionized this process by integrating all these functions into a single automated system. Now, with one continuous workflow, beams can be fed, drilled, punched, marked, and cut—all controlled by CNC (Computer Numerical Control) software.

This shift means:

- Faster turnaround times for projects

- Improved accuracy across complex beam profiles

- Reduced labor dependency

- Lower material wastage

CNC H Beam Drilling Line: Precision Where It Matters

Among the most widely used systems is the CNC H beam drilling line. H-beams are essential in construction for their ability to withstand high loads, but they often require intricate hole patterns for bolting and welding.

A CNC H beam drilling line offers:

- Multi-face drilling (top, bottom, and sides in a single setup)

- Automatic tool changing for different hole sizes

- Laser alignment for accuracy

- Positioning sensors to reduce rework

By combining speed with precision, this machine ensures that every drilled hole is placed exactly where structural integrity requires it.

CNC I-Beam Processing Machine: Meeting Complex Project Demands

While H-beams are common, I-beams remain the backbone of many high-rise and industrial structures. The CNC I-beam processing machine is designed to handle these beams efficiently, automating cutting, slotting, drilling, and marking.

Key benefits include:

- Automatic beam feeding rollers that reduce handling time

- Integrated cutting stations for fast sectioning

- Software-controlled programs to repeat designs with zero variation

Whether it’s for bridges, industrial plants, or transmission tower parts, the CNC I-beam processing machine ensures consistency across every single component.

Structural Steel Beam Line Machine: Heavy-Duty Performance

When large-scale projects call for high volume and heavy materials, the structural steel beam line machine is the answer. These machines are built to handle massive beams while maintaining precision.

Why it’s crucial for modern construction:

- Handles thicker and heavier profiles with ease

- Designed for long production runs without downtime

- Ensures uniformity across hundreds of beams

- Enhances safety with enclosed cutting zones and emergency stop functions

This makes it indispensable for megaprojects where timelines are tight and reliability is non-negotiable.

Beam Punching and Drilling Line: Speed Meets Flexibility

Not all projects require cutting—sometimes punching and drilling are the priority. A beam punching and drilling line specializes in these tasks, ensuring speed without compromising quality.

Advantages include:

- High-speed punching for bolt holes and slots

- Dual-sided drilling without repositioning

- Programmable patterns for complex layouts

- Reduced operator intervention, lowering fatigue and error rates

In projects such as transmission towers, where thousands of punched and drilled holes are needed, this system saves weeks of manual labor.

Automatic Beam Cutting Machine: Efficiency at Its Core

No beam fabrication line is complete without cutting. The automatic beam cutting machine ensures beams are sized to exact project requirements. Using CNC control, these machines can cut straight, angled, or complex shapes with remarkable accuracy.

Highlights:

- Fast throughput with minimal scrap

- Thermal cutting technologies (plasma, oxy-fuel, or laser)

- Integration with drilling and punching lines for seamless processing

- Reduced re-handling, as cutting is part of the same flow

This integration reduces downtime between fabrication stages, keeping projects on schedule.

Why the CNC Beam Fabrication Line Is Indispensable

So, what makes the beam fabrication line the backbone of modern construction? The answer lies in its ability to merge automation, accuracy, and efficiency into a single solution.

1. Time Savings

Large projects can involve thousands of beams. Automating fabrication reduces processing time from hours to minutes.

2. Error Reduction

CNC software ensures every cut, hole, and punch follows exact specifications—minimizing costly rework.

3. Labor Optimization

Instead of multiple workers handling separate machines, one operator can oversee the entire line.

4. Material Utilization

Accurate nesting and cutting reduce wastage, directly lowering project costs.

5. Scalability

Whether producing a handful of beams or thousands, CNC beam fabrication lines adapt to demand.

Applications Across Industries

The versatility of these systems explains their widespread adoption:

- Construction of high-rise buildings: Beams are processed quickly and precisely.

- Transmission towers: Thousands of punched and drilled holes can be completed with speed.

- Bridges and highways: Large-scale structural beams require flawless processing.

- Industrial plants: Consistency across massive projects ensures smooth assembly.

Everywhere structural steel is used, CNC beam fabrication lines add value.

Conclusion

From skyscrapers to transmission towers, the CNC beam fabrication line is the unsung hero of modern construction. By combining cutting, drilling, punching, and marking into one streamlined process, it saves time, reduces errors, and ensures structural integrity.

For construction companies striving to stay ahead in today’s fast-paced market, adopting advanced solutions like the CNC H beam drilling line, CNC I-beam processing machine, structural steel beam line machine, beam punching and drilling line, and automatic beam cutting machine is not just an upgrade—it’s a necessity.