When it comes to building a steel fabrication workshop that runs efficiently and delivers consistent quality, investing in the right equipment is a decision that can make or break your success. Among the essential tools, a CNC angle line machine is a cornerstone for fabricators dealing with angle steel, channels, and complex structures. But not all machines—or manufacturers—are created equal.

Choosing the right CNC angle line machine manufacturer isn’t just about the price tag. It’s about reliability, performance, after-sales support, and how well the machine fits into your existing operations. In this blog, we’ll walk you through what you should consider when selecting the best manufacturer or angle line machine supplier for your needs.

1. Understand Your Fabrication Requirements

Before you start evaluating manufacturers, make sure you’re clear on what you need from the machine. Are you working on structural steel for bridges, towers, or industrial buildings? Will you be handling only angles, or do you also need to process channels?

Machines vary in terms of punching speed, cutting accuracy, and automation features. The right CNC angle line machine manufacturer will offer solutions tailored to your workload and output expectations. Whether you’re a small workshop or a large-scale fabrication unit, clarity in your requirements will help you avoid overspending or underperforming.

2. Look for Industry Experience and Specialization

Experience matters in manufacturing. Manufacturers with a solid track record in steel fabrication machinery typically have a better grasp of real-world challenges. A company that specializes in CNC solutions for structural steel fabrication is more likely to provide robust machines that are well-engineered and easy to maintain.

Always check the manufacturer’s portfolio, previous installations, and client references. A trustworthy angle line machine supplier won’t hesitate to connect you with past clients or offer you a live demo. Their specialization in specific fabrication niches can also lead to more relevant technical recommendations.

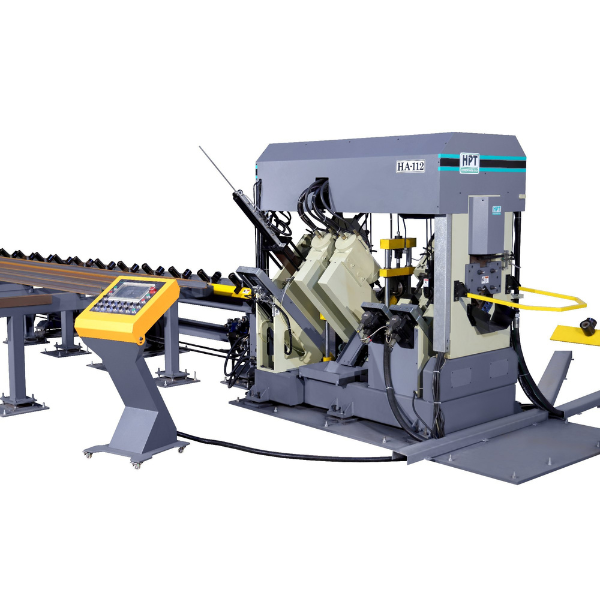

3. Evaluate Technology and Build Quality

Modern metal fabrication equipment needs to be fast, precise, and reliable. You’ll want to inspect the CNC controller, hydraulic systems, tooling design, and the build quality of the machine itself. Ask the manufacturer questions such as:

- What brand of CNC control system is used?

- Are software updates easy and frequent?

- What types of punches and dies are available?

- How quick and easy is tool replacement?

- Is the machine designed to handle heavy-duty fabrication?

The best CNC angle line machine manufacturers are transparent about their technology stack and use globally recognized components. These features make a difference in the long-term reliability and efficiency of the system.

4. Check for Customization and Integration

No two workshops are the same. A manufacturer that offers customization options based on your floor space, output, and workflow will be a valuable partner. Whether you need integration with existing metal fabrication equipment or additional features like automated marking or material handling, customization ensures maximum ROI.

Good manufacturers will visit your site (physically or virtually), evaluate your current setup, and offer tailored suggestions to streamline your operations.

5. Local Support and Training Services

One of the most overlooked aspects when choosing a CNC angle punching machine manufacturer is the availability of after-sales support. Even the best machines require servicing, software updates, and sometimes emergency repairs.

- Choose a manufacturer or angle line machine supplier that offers:

- On-site installation and operator training

- Remote diagnostics and software support

- Readily available spare parts

- Detailed user manuals and training guides

Local or regional support can drastically reduce machine downtime, helping you maintain steady production schedules.

6. Compare Cost vs. Long-Term Value

Price is important, but value is critical. Instead of opting for the cheapest machine, consider how well it performs, how long it will last, and how it affects your operating costs. Evaluate:

- Power consumption

- Throughput and efficiency

- Maintenance costs

- Availability of consumables

- Warranty and service plans

Leading CNC angle line machine manufacturers provide comprehensive service packages, flexible payment terms, and upgrade pathways that make the purchase a smart investment.

7. Ensure Compliance and Safety

Compliance isn’t just about ticking boxes—it protects your workers and helps avoid legal trouble. Make sure the steel fabrication machinery you’re buying complies with relevant safety and industrial standards. Look for certifications and build quality that meet international benchmarks.

Machines should have protective barriers, emergency stop features, and easy-to-read warning indicators. It’s also good to know if the manufacturer offers safety training.

8. Learn from User Reviews and Client Feedback

Dig into customer feedback before finalizing a supplier. Reliable metal fabrication equipment manufacturers usually have client testimonials, detailed product documentation, and online reviews. Visit industry forums, watch YouTube demos, or talk to current users if possible.

A quick way to test their reputation is to ask for a virtual or in-person demo. Any trustworthy supplier will be more than happy to show their machine in action.

9. Plan for Future Growth

Your workshop may expand in the future. Choosing a CNC angle line machine that can scale with your growth is a smart move. Whether it’s automation modules, software add-ons, or multi-size punch compatibility, future-proofing your investment ensures you won’t need a complete overhaul later.

Discuss your long-term goals with the CNC angle line machine manufacturer. A capable partner will guide you toward equipment that supports both your current needs and future aspirations.

Final Thoughts

The decision to invest in a CNC angle line machine is not just about hardware—it’s about choosing a partner that supports your growth, minimizes your downtime, and maximizes your efficiency. With the right CNC angle line machine manufacturer or angle line machine supplier, your workshop can produce faster, safer, and with greater precision.

Be clear on your needs, explore your options, and don’t hesitate to ask questions. A bit of due diligence now can result in years of hassle-free operations and strong returns.